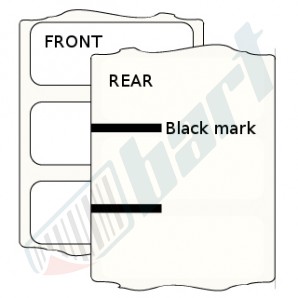

Labels with a black marker on a silicone backing

|

Labels with a black marker on a silicone backing. Labels with a black marker on a silicone substrate. The black mark is printed by a flexographic machine printing on non-adhesive and self-adhesive labels. The print is usually made on the reverse side of the label or on the silicone substrate. Some labels do not have a side cut or spacing between labels that are specifically used to recognize subsequent labels by the printer. Transparent film labels often cause problems. The label printer’s photocell cannot recognize the material’s transparency because the material is 100% transparent. The label printer’s photocell recognizes transparencies and gets lost when the top material is transparent. The solution to this problem is to print a black mark - MARKER. The downside of this solution is the higher cost of the label because it contains additional prints. Transparent biodegradable films made of cellulose have also appeared on the market. The black strip is printed across the width of the silicone substrate tape, and its height is almost always equal to the spacing between labels. The height of the strip varies depending on the die used on a given roll. Black marks are rarely used for paper labels when the printer has an unusual system for recognizing spacing between labels, when it has an unusual shape or is round and the printer does not have a movable sensor for subsequent labels. For film labels, especially transparent ones, white glassine 65 silicone substrates with a thickness of 55 microns or high density 70 wh with a thickness of 56 microns are recommended, i.e., white substrates rather than honey or yellow ones. They are well suited for photocell-assisted labeling systems because they print well and create good contrast. White Kraft substrate is not suitable for film labels with black markers as it prints poorly and is more difficult. |

Email query Form query Phone +48 61-28-58560