Products

GALLERY

|

|

|

|

|

|

|

|

Here we present our products. BART The company distributes and implements professional equipment and production services. In the side menu on the page, there is a detailed description of each product, specifications, manuals (user's manual) and comparative data that allow detailed analysis of the product, device drivers. We strive to meet your individual needs and provide you with only the highest quality solutions.

COLOUR LABELS

We specialize in the production of colored labels. In our company we use the label printing methods: flexography, letterpress, inkjet, cold stamping and screen printing (through sieve). Color Printed Labels (flexography method), with lacquer, are designed to stick to products, packaging, etc. These are best-selling our customers a kind of decorative accessories. Flexo method is constantly modernized and improved. This technology is currently dominated by polygraphy.

The advantages of flexo is, among others.

- Simple construction of the printing system,

- The ability to print from a relatively high speed,

- Printed ribbons both absorbent and non-absorbent substrates

- Use a wide variety of colorful paint.

One of the main advantages of flexo is relatively quick to prepare machines for printing. Our company is able to perform each project in flexography. We use a machine with a narrow flexographic printing. This machine is designed for printing and processing self-adhesive labels and packaging (labels, stickers, tickets, caps and more stable materials with a thickness of 30 to 350 microns). The width can not be greater than 250 mm and 340 mm. The machine allows the drying of UV varnishing, lamination, cold foiling, flip the labels after the first team, inverted overprint, video-inspection system labels. UV drying improves the quality of printing, allows the use of UV coating options. This method and this machine produces a small amount of waste.

Flexographic Printing - PAINT

The main advantages of flexographic inks should include a very fast drying time. This method allows you to instantly obtain a dry surface. Allows you to print with less ink layer thickness on a printing plate. UV flexo inks are suitable for printing non-absorbent and absorbent materials. Today's UV inks are made in accordance with the requirements of environmental protection. Their composition, are renewable resources, such as vegetable oils (not mineral). In the manufacture of paint used is water that replaces solvents.

Flexographic Printing - VARNISH

The purpose of the use on labels LACQUER lab is to give a high gloss or matt and protection against damage printed image surface. That extends its durability and improves the quality. VARNISH makes increases the level of gloss, color saturation, sharpness, and the extent of total drawings. UV Varnish forms a coating. This allows a very high resistance to various chemical effects, temperature, and the action of mechanical forces. UV Lacquer lets you get a similar effect as in the case of lamination. UV lacquers contain no solvents (100% dry matter), therefore are considered environmentally friendly. UV curing is carried out immediately after application of paint and takes a split second. UV varnish can also be used when working with materials, which are to be manufactured in food packaging.

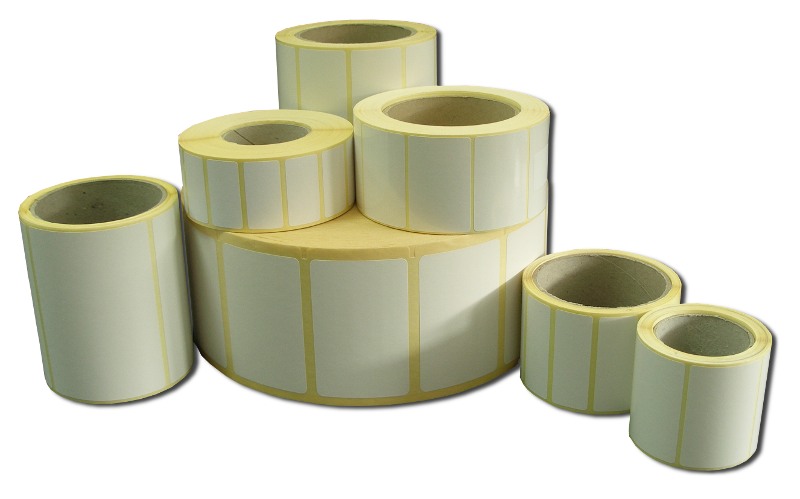

LABELS WITHOUT OVERPRINT

Self-adhesive labels without printing in A4 format, are designed for inkjet and laser printers. Self-adhesive labels with adhesive and non-adhesive labels, unprinted, wound on roles, are intended for printing on thermal printers and thermal transfer. Our company has been producing self-adhesive labels, intended mostly for printing variable data. Depends on the function, which is to perform label.

Should be adapted to the appropriate material.

The most popular self-adhesive labels with materials such as:

- GLOSS paper with strong adhesive and a standard,

- MAT paper with strong adhesive and a standard,

- GLOSS paper with glue on freezing, and label with removable adhesive,

- ECO thermal paper,

- Fluorescent paper,

- Thermal paper TOP

- Plastic labels of PP and PE (100-180 g/m²),

- Paper GLOSS-T (TYRE)

- Cardboard label (100-240 g/m²).

We can produce labels that are resistant to high and low temperature, weather conditions, mechanical damage, as well as solvents and other harmful agents. Examples of such labels are:

- ALU-ALU-S and TT

- PET and PVC (180-300 g/m²),

- VINYL,

- Nylon and satin.

We produce labels sealing, which burst when removing or leave graffiti on surfaces which have been peel off. Labels of this type are used wherever relevant to the disclosure of the fact violating the integrity of the product for which it was affixed. An example of such self-adhesive labels are:

- VOID mirror,

- ACE - VOID crushing and dull,

- Holograms.

PAPER LABELS

Production of paper labels in our company based on the use of high-quality paper, delivered by recognized manufacturers worldwide. We use all available types of glue and paper. Our offer includes both paper labels with special properties (adhesive standard, strong, and the adhesive approved for use in food), self-adhesive labels, thermal labels, thermal transfer labels and cardboard labels. Our company can produce a matte labels, glossy paper and thermal labels in any color. We have a wide selection of sizes and shapes of knives for cutting (punches).

SYNTHETIC LABELS

Production of foil labels is no different in principle from the production of paper labels. In the case of film labels, their use is different. Foil labels are used when the material of the paper is too weak. Foil labels are used in the production of specialty labels, such as warranty seals, security labels, and crushing and front panels. Group labels are divided into foil: PE, PP, PET, PVC, Tyvek.

Labels PE are made of foil "polyethylene" low density (ie high pressure) and are used primarily in the packaging industry. Labels PP "Polypropylene" Similar techniques are performed which is used for the production of PE foil labels. Production of PP and PE is one out of a group of high-quality packaging materials. PET films "poly ethylene terephthalate," commonly referred to as polyester films are used in the industry, linked to the production of packaging. Currently, the best known is the synthetic paper Tyvek. It is a synthetic paper made without the addition of adhesive with 100% high density polyethylene. Tyvek is made from very thin (0.5-1.0 mm) and an infinitely long fibers, which are linked together under pressure and high temperature. This material resembles paper naturalny.Tyvek is a material extremely strong and resistant to abrasion, water, rot, chemicals and decay.

SELF-ADHESIVE AND NONE-ADHESIVE

Adhesives in the specified temperatures are characterized by a permanent adhesive properties and immediate sticking with sufficient force to different surfaces. The greater this force, the higher the level of adhesion. Labels with glue in a liquid state, the imposition of the substrate are adhesive. In the solid state - the dry adhesive film, formed after drying or cooling, is much more grip. Adhesives can be divided into two groups: permanent and removable adhesives adhesives.

Permanent adhesives have a high tack (adhesion) to the surface on which they are stuck. The use of labels with the super strong glue, makes the subsequent separation of the label without destroying it is impossible. With a strong adhesive labels are used most often at low temperatures and for deep-freezing. Labels with glue standard (general purpose) are used for simple applications on smooth and dry surfaces. These labels are not used in an environment where they are exposed to extreme weather conditions. Underside of the adhesive material is usually paper, with the properties - "abhesive". This material is coated with a layer of silicone that protects the pressure-sensitive adhesive layer against self-glued. This allows easy separation of the silicone paper from the adhesive layer and the bonding adhesive material on the surface.

BARCODES

One-dimensional bar code is a pattern of bright and dark stripes (bars). A model for structured and readable identification systems for devices. Bar codes are used for fast and error-free reading of information hidden in the code. Bar codes allow efficient identification of products. A bar code is currently the most popular technique of automatic identification of goods, logistics facilities and other equipment. Bar codes are used in almost every area of the economy. A barcode must be strictly defined dimensions and proportions. Barcodes can be printed by label printers and dot matrix printers, laser printers, inkjet printers, etc. The best quality (the best read) code is obtained through the work of thermal printers and thermal transfer printers.

Such a result is due to the method of printing, used in these printers.

The most popular bar codes are:

- One-dimensional codes (UPC-A, EAN8, EAN13, ITF, Interleaved 2of5, Codabar, Code 39 - Full ASCII Code 39 - Regular, Code 93, EAN / UCC Code128)

- Multi-dimensional codes (PDF417, DataMatrix, QRCode, MaxiCode, UPS, MicroPDF417, MicroQRCode).

LABLEL PRINTER

Our printers can print labels from the role. They allow you to print a relatively large amount of information, graphics, text and bar codes. The most important element is the printer's print head, consisting of hundreds of heating elements, each of which corresponds to one point on the printout. Label Printers can be grouped into two modes: thermal and thermal transfer. In thermal transfer printing mode used thermal transfer foil. Thermal Transfer foil is coated with a substance that is a mixture of wax and / or resin. At the time of print head are moved labels and thermal transfer foil. As a result of heat generated by the head, the substance of the film is melted and migration on the label. Ribbons have different proportions of wax and resin. In the heat mode thermal printing on the label on the label is covered with a layer of thermo-sensitive, which changes color when exposed to heat. Thermal labels have a limited life printing. They should not be exposed to sunlight and heat.

BART The company provides services in repair and maintenance TSC label printers and Zebra label printers. We advise on correct use of equipment. We have specialized technical support and spare parts warehouse for our printers. We have many years experience in selling different brands of thermal label printers, thermal transfer printers, color label printers. On the Polish market, we represent companies such as:

TSC (equivalent Birch, Toshiba TEC), Zebra, F + D.

For all label printers attached is transparent software and drivers. PPUH BART service company enjoys a very good reputation among many customers. We offer label printers, under 24-month warranty and service (12 month for printhead).

When selecting your label printer is worth paying attention to:

- Types of materials, which enables the device output, and those that can not be used in a particular model,

- The practical availability of supplies.

In the selection of label printers are important parameters such as:

- Print type: thermal / thermal transfer,

- Maximum width of the print or web,

- Transfer ribbon core diameter: 1 inch / 0.5 inch.

PRINTHEAD

The most important element of a thermal printer and thermal transfer print head is. The printhead consists of hundreds of heating elements. Each heating element corresponds to one point on the printout. During the print head are moved into the label. In the case of thermal transfer printers and thermal transfer foil is moved. The image is built from the points - a mosaic. Resolution is the number of image points, which can be placed on a specific area. It is also a parameter of the size of points. Point size and print speed are key points of the head parameters. The unit is dpi print resolution (dots per inch). Offered by BART heads have a resolution of 200, 300 and 600 dpi. 300 dpi resolution means that 1 inch in length or width of the falls 300 points. When the resolution is low, the print is so visible. stepped effect - diagonal lines are not smooth, diagonal lines are jagged, serrated. The heads can print at different speeds. Print speed depends on the cooling of the heating elements. Cooling occurs after every print cycle. The printers can be found two types of heads: flat and the edge (less common). Label Printers can be grouped on the thermal and thermal transfer. In thermal printers, printer head prints on the label covered with a layer of thermo sensitive. This layer changes color when exposed to heat. In thermal printers, printheads directly burn the information on heat-sensitive paper. Contact the printhead with the paper has a strong influence on the stability of this most important element in the device. In the case of thermal transfer print mode used thermal transfer film. Film surface is covered with dye staining substance. The dye enters the wax film and / or resin. As a result of heat received by the head, the substance of the film melts and is migrating to the adhesive label. We provide you heads covered by a 12-month warranty and service of our company. We recommend the heads of recognized brands in the industry - TSC, Zebra, Birch, F + D, MPH are just some of them.

TRANSFER RIBBONS

"Films" are known as TTR - Thermal Transfer Ribbons otherwise transfer or ribbons. These are polyester foil with dye. We offer TTR that stand out performance and also provide head protection against dirt and durability of prints. We have a wide range of films that can be used in any thermal transfer printer. We have a ribbon of wax, wax resin, resin - both black and color. Width of ribbon coloring ranges from 40 to 210 mm. Ribbons (coloring), can be bent to the inside (IN) or outside (OUT). Dye foil type should be chosen according to the type of label on which you want to print. Important. Thermal transfer ribbons stored in damp or exposed to sunlight may be damaged.

BARCODE READERS DATA COLLECTORS

Barcode reader (barcode scanners) and a collector of data (often referred to as mobile terminals) are used to read information in the automatic identification systems. We offer equipment from brands such as Symbol, Motorola, Datalogic, EIA, Honeywell, Metapace, Glancetron, UNITECH. We guarantee the proper functioning of each code reader in the everyday, several hours' use.

Our facilities feature:

- Long service life (durability),

- Very good resistance to falls and injuries, mechanical (strength),

- Effective action in mitigating errors due to reading obscure codes

- A multitude of ways to transfer data

- High functionality,

- Attractive design.

By using a barcode reader and a data terminal gain, among others. speed data entry, improve efficiency and comfort, reduce consumption of documents "paper". The two most well-known method for reading bar codes are read linear and matrix. Reading is a linear LED. For this reader, the LED lights generate light and analyze the reflected beam detector. The second, equally well-known method of reading relies on a linear laser. The technique involves moving the point of the laser through a mirror and create the same effect of the line, while analyzing the reflected light by diode detection. Laser Scanner ensures proper code reading from a distance and effective action when working outdoors. Due to the presence of moving parts, this device, however, is characterized by a lower degree of resistance to mechanical damage and downs. LED scanner distinguished by low power consumption. Barcode scanner manual wire is used most often in places where there is high levels of customer service and there is no need to transfer devices. In the warehouses, as well as various types of facilities where it is necessary to use equipment, ensuring mobile use, ideal for cordless scanners. This equipment can read the labels, placed anywhere. The use of wireless scanners eliminates the difficulties arising from a large distance from the position of the spot commodity and the limitations associated with the use of the cable.

LABELS WINDER

"Labels winder" are used for winding the labels on the role. These devices allow you to rewind the labels on the cardboard sleeves. The presented equipment is ideal for situations where labels printed on a printer are enormous quantities of labels.